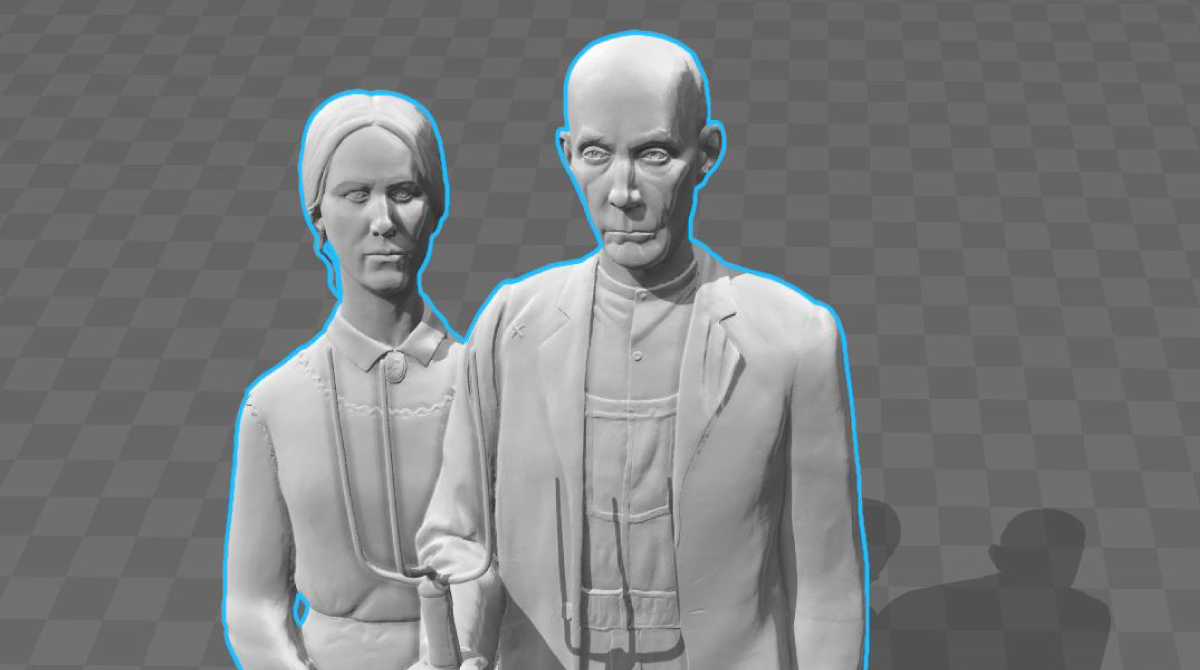

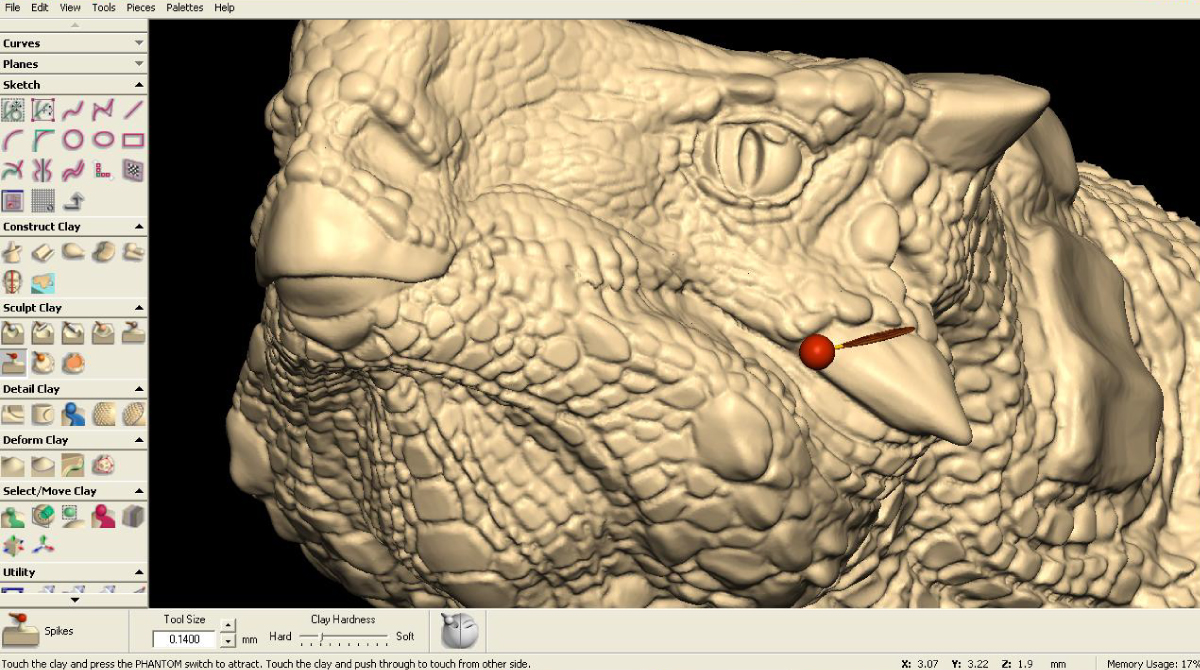

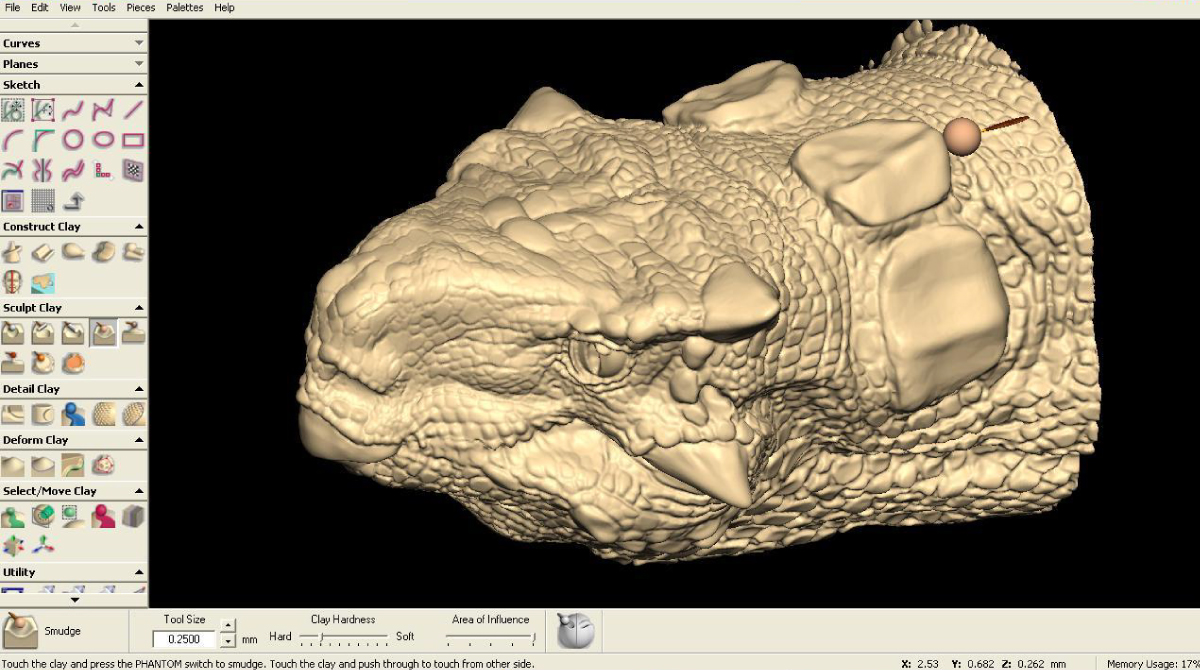

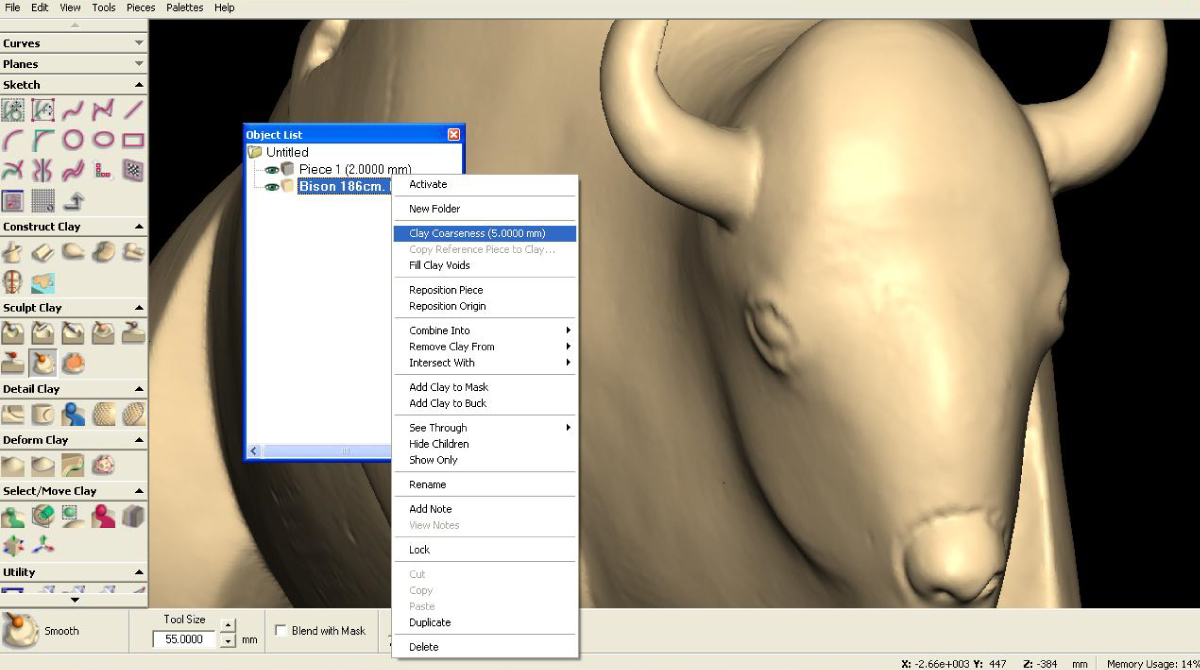

TMC has established our digital studio in 2007, we are the first fine art casting foundries in Asia that offers the completed digital enlargement service through the use of 3D laser scanning and CNC polystyrene milling. We also explored and utilized the Rapid Prototyping technology by providing the 3D ABS printing service for the small items through the Stratasys Dimension Elite which was the stage of the ache machine at the time. Our digital studio has completed my interesting and challenging projects for our clients over the years. In many cases, artists just came up with sketches or rough ideas – we work together with them exploring the alternatives, develop strategies to realize their project through the 3D technology.

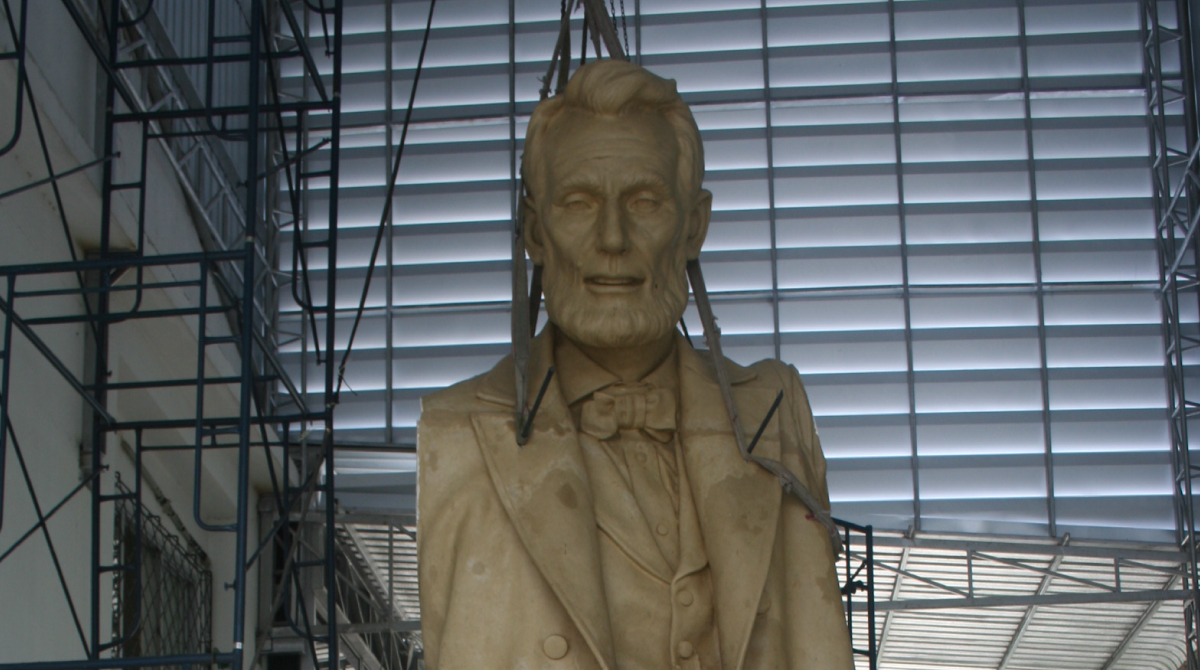

The corporation of the 3D technology allow our clients’ project to be completed in a remarkable timeframe. Example for such case would be the completion of 25’ monumental figures that has taken only seven months from scratch to completion, three months for model building and another four months for molding to metal finishing.

Now TMC digital studio, we have three CNC 4 axis polystyrene milling machine in service together with five FDM (fuse deposition modelling) 3D printers that has the possible building area of 100 x 100 x 100 centimeters.